|

Rigid®

Airship Design N.V.

is a Dutch consortium whose purpose is the development and commercial manufacture of Rigid®

airships. It was officially formed on 26 May 1998. Its aim is to start building a prototype airship at the earliest opportunity, followed by the mass production of airships at its new production complex in Lelystad, on which construction work will begin this year. Rigid Airship Design N.V. believes that in the 21st century there will be a large market for airships as a silent, safe, energy-efficient, cost-effective and multifunctional alternative for transport, observation, data communications, promotion and tourism.

The Shareholders

Rigid Airship Design N.V. brings together the combined knowledge and capital of leading Dutch companies to develop an idea put forward by the Scottish airship expert Ian Alexander. RDM Aerospace N.V. via amongst others Nevesbu (the designers of ships and submarines), and Stork N.V. via Fokker Aviation, are providing technical input. Greenfield Capital Partners B.V., M. Caransa B.V. and the project initiator Airshot International N.V. are supplying the start-up capital.

The share allocation in Rigid Airship Design N.V. is as follows:

| RDM Aerospace N.V. |

42.3% |

| Airshot International N.V. |

36.3% |

| Stork N.V. |

10.0% |

| M. Caransa B.V. |

7.0% |

| Greenfield Capital Partners B.V. |

4.4% |

The Company

An airship is in engineering terms something of a hybrid; it is neither a ship nor an aeroplane. Its design calls on an extraordinary breadth of disciplines. This is reflected in the make-up of the company. Apart from a core group of airship experts, the team includes displacement experts from

Nevesbu

(traditionally a ship and submarine design company) and from

Fokker Aviation

. Together they provide the full spectrum of skills and facilities required for the NL-1 project. Its design staff has undertaken technical and feasibility studies and produced a basic design for a 180-meter long airship, the RA-180. This design will be developed in detail and submitted to the RLD for its approval before the construction of a prototype can begin. Rigid Airship Design N.V. hopes to have this prototype, provisionally named the RA-180, ready for test flights by the end of 2001, with certification following thereafter. Mass production can then start, after the certification process is complete.

The construction work will be sub-contracted as much as possible. Final assembly will take place in Lelystad under the supervision of

RDM Aerospace.

Project leader

"Mr. Ian Alexander"

|

|

The man behind the project, Ian Alexander (54), has devoted his entire life to airships and has worked on a number of successful airship projects before. Increasing pollution, traffic congestion and various market surveys have all strengthened his conviction that the time has now come to reintroduce the Rigid airship. Since arriving in the Netherlands in 1995, Ian Alexander has been working on plans for the design of a Rigid airship based on the latest insights, techniques and materials. Rigid Airship Design N.V. was established in 1998 with this aim in mind.

|

|

THE AIRSHIP: MORE THAN JUST A TEST BALLOON

Market research has shown that there could be a considerable market for airships in the 21st century. The potential market for large airships capable of performing a variety of sometimes unique functions is estimated at more than 1,000 vessels worldwide. Rigid Airship Design N.V. believes it can serve a substantial proportion of this market.

Starting with straight-forward maths and physics, we can determine that one cubic meter of helium lifts 1 kg of mass. The total lift is therefore a function of volume. Double the dimensions of an airship and the volume increases by a factor of 8, but costs by only a factor of 4. This means, critically, that the larger the airship, the better lift / cost ratio and the better the return on your investment.

THE RIGID AIRSHIP: SAFE, RELIABLE AND ENVIRONMENTALLY FRIENDLY

Rigid Airship Design N.V. plans to have the first prototype ready for test flights by the end of 2001. The only similarity between this ‘Rigid’ airship, the RA-180, and the old Zeppelins is its outward appearance. The material systems are quite different. Wherever possible RAD sticks to the known and proven principles established by earlier operators. They are highly advanced and will make the RA-180 strong, reliable and above all extremely safe. Rigid Airship Design will use world-class design, engineering and construction companies within the consortium.

MINIMISATION OF OPERATIONAL RISK

-

In combination with the RLD (the Dutch flight certification authorities), RAD are developing standards of safety on a par with any aircraft.

-

No Zeppelin ever failed in flight through structural failure. Accidents resulted either from hydrogen (which has now been replaced by non-inflammable helium) or from limited understanding of the forces involved (now known to all approved designers!) or from poor understanding of the weather, a problem overcome by modern avionics.

-

RAD has an extraordinary breadth of airship experience, knowledge and technical excellence. This will be reflected not only in the construction but also in operations.

|

|

Rigid Airship Design has opted for non-combustible helium to guarantee the absolute safety of passengers and cargo. If helium comes into contact with fire, the fire is quenched. It is therefore completely safe to locate the engines under the skin. This not only makes the airship more quiet but also allows in-flight maintenance to be carried out . If one of the cells should spring a leak, this will not affect the progress of the flight in any way, since the vectoring propellors will guarantee a wide safety margin in combination with the water ballast that can be jettisoned.

Environmentally friendly

Airships have many advantages over and above other forms of air, land and water transport. To begin with, they are quiet, clean and energy-efficient. To keep an airship aloft, all that is needed is to fill it once with non-combustible helium, which is widely available. Relatively little fuel is needed for propulsion. The airship’s low noise emissions make it extremely useful for flying over densely populated areas and areas governed by strict noise restrictions.

Efficiency

The airship’s relatively low running costs and the fact that it needs no expensive infrastructure with runways, roads or rails makes it a cost-efficient form of transport. An airship can land and take off from almost anywhere provided there is a mast and a turning space that has a diameter roughly equal to twice the length of the airship. This makes the airship a perfect transport alternative in densely-populated areas, as well as a useful method of transport in developing countries with inadequate infrastructure. The land on which the mast is located may possibly also be used for other purposes such as grazing or crop-growing. Finally, airships will occupy the 500 – 1,500 metre air corridor, which means that the available airspace will also be used efficiently.

Operating caracteristics

An airship such as the RA-180 developed by Rigid Airship Design N.V. can reach a maximum speed of 148 km/hour, has a maximum radius of action of 20,000 km or can remain in the air for weeks at a time. It can relatively quickly reach places or objects that are difficult to access, such as locations at sea or remote regions. Moreover, it can take off and land almost anywhere and under almost any conditions to pick up or drop off passengers and/or cargo, and can hover over the same spot for at least several days.

Stability and safety

Rigid airships guarantee stability and comfort. Thanks to their ideal flying properties, passengers will hardly notice they are in the air. The airship is in perfect balance with its surroundings. It behaves more like a fish in water than a bird in the air – it is at home in the medium in which it operates with all the benefits which this brings. Other safety guarantees are the non-combustible helium which gives the vessel its lift, the separate gas compartments which ensure that in the event of a leak there are no acute negative repercussions, the Rigid construction, the reliability of the vessel’s six engines and its state of the art on-board navigation and communications equipment. The airship can take off, cruise and land in roughly the same weather conditions as those which apply to aircraft.

WHY USE AIRSHIPS?

-

By definition airships are lighter than air. Traditional aircraft expend enormous amounts of fuel staying aloft. Airships require fuel only for motive power. Traditional aircraft require correspondingly greater horse-power, sophisticated and massively expensive jet technology. The rigid airship requires only simple reciprocating engines. This key fact allows for inexpensive maintenance regimes, greater aircraft utilization and cost reductions throughout the value chain.

-

With vertical take-off airships do not require traditional airports with long runways; they simply need a mast. The operators can therefore avoid the high costs and congestion of modern hubs and take advantage of "point to point" delivery options. The passengers can avoid the traffic-jams and the crowds.

-

Airships transform the flying experience. Cruising quietly at 1500 feet in spacious surroundings, passengers are not confined to seating, but are free to move about and enjoy the view.

-

Airships use marginal airspace. In spite of cluttered skies, the airship occupies the segment unused by commercial aircraft (from ground level up to 5000 feet). Airships do not stretch existing systems, they complement them.

WHY USE RIGID AIRSHIPS?

-

Allows for internal accommodation (i.e. passengers / freight are carried within the structure and not in an external gondola)

-

Safest airship design available. It is the only type of airship with the proven capability to maintain control and structural integrity at flight speed in the event of loss of a gas containment element.

-

The rigid structure prevents flexure and thereby offers speed advantages of up to 10% over non-rigid forms

- Mooring systems for rigid airships are well established.

|

TRANSFORMED FLYING EXPERIENCE

Why does everyone like the idea of flying but hate scheduled flights? Because jet aircraft are boring, uncomfortable (unless you pay an extra $1000 for leg-room) and there is nothing to see except clouds. Your feet swell, and by the time you arrive at your destination you feel like you just walked all the way. Aeroplanes are extraordinarily good machines if you have to be in New York for a business meeting in a short time time but is it leisure?

Imagine a flight at only 1500 feet, where passengers are not confined to their seats, and are able to appreciate the extraordinary views. They have access to restaurant accommodation, bar areas and recreation facilities. The cabin is not pressurised. In short, people can really begin to enjoy flying again.

Yet RAD will provide these luxury leisure vehicles at a cost (including through life costs) that bears no resemblance to standard aviation pricing. The simplicity of our technology gives extraordinary aircraft availability. Our fuel usage, noise output and emissions are very low. And vertical take-off gives us access to low-cost green field sites. Passengers do not have to queue in traffic jams to get to busy hub airports (and operators do not have to pay hub prices).

If your business is scheduled or unscheduled transport of passengers or above all if your business is about leisure, the Rigid Airship affords extraordinary opportunities. Together we can create the first aerial tourism market for mass exploitation.

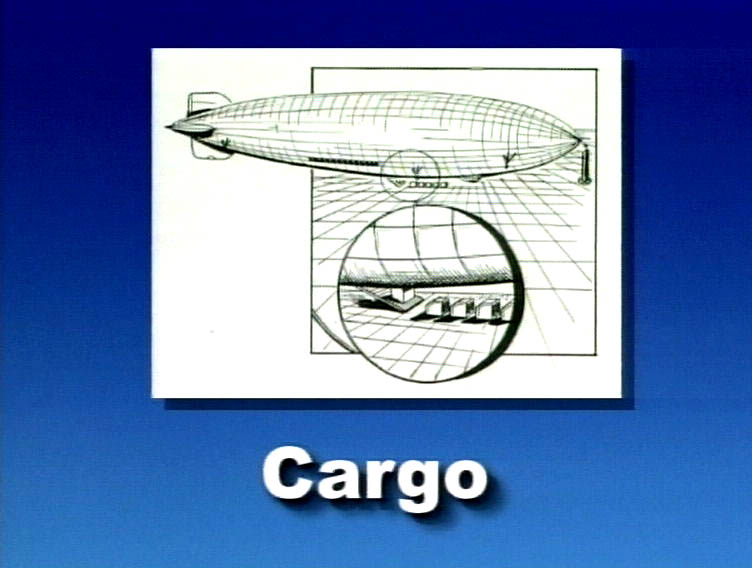

FREIGHT

COMPETITION ON COST vs TRADITIONAL AIR FREIGHT

- Low operating costs

- Low technology

- Low fuel consumption

- Cheap airfields

GENUINE GLOBAL RANGE

Point to point options

- Not limited by runway availability

- Distribution from the point of manufacture

- Keeps clear of congested hubs

- Low noise emissions

Not dependent on hi-tech jet maintenance regimes / aviation fuel availability

Extraordinary range (+ 20,000 km) for surveillance.

FREIGHT ADVANTAGES

Not constrained by volume

(unlike aircraft with limited freight compartments).

- Optimised for low density high volume goods

Extraordinarily smooth flight

- Optimised for delicate goods and/or live stock (e.g. race horses)

Incremental revenues from advertising

- Consider the promotional opportunities of flying a 600 feet long aircraft at 1500 feet over new markets

SURVEILLANCE

ADVANTAGES OVER TRADITIONAL PATROL AIRCRAFT

ENDURANCE

- Time on task measured in weeks

- Comfortable accommodation

COST

- Low maintenance requirement

- Low fuel usage

- Low in life costs

RANGE

PAYLOAD

- Useful lift of prototype in the region of 35 tonnes

covers all surveillance requirements

TASKING

- General surveillance

- General border work

- Drug patrols

- Monitoring of 200 mile zones

- Navigational safety work / surveys

Communications data link facilities

- ASW / AEW / C3

- Search and Rescue

- Disaster relief

ADDITIONAL MARKETS

-

PROMOTIONAL

-

exploiting promotional aspects of the largest aircraft in the world in conjunction with other roles (i.e. surveillance / TV etc.)

-

ELECTRONIC

-

providing airborne platform for broadcast / mobile communications / data-links

-

SPECIAL SUPPLY

-

Supply to oil platforms / special facilities outside the range of traditional helicopters

-

THIRD WORLD ECONOMIC DEVELOPMENT

-

Airships combine many features suited to the development of Third World countries. They can support mineral extraction and trade from areas of poor infrastructure without the burdens of high investment or large facilities. They use appropriate technology and have no environmental impact.

|

| 1ST AIRSHIP DATA

|

SPECIFICATIONS

|

| LENGTH OVERALL |

180m |

| MAX DIAMETER |

30m |

| FINENESS RATIO |

6.0 |

| GROSS VOLUME |

83,100m3 |

| MAX GAS VOLUME |

75,000m3 |

| PROPULSION SYSTEM |

6 x 600HP |

| USEFUL LIFT |

35 TONNES |

| RANGE |

20,000 KM |

| MAX SPEED |

148 KMPH |

Rigid Airship Design N.V. plans to have the first prototype of the

RA-180

ready for test flights and certification by the end of 2001.

|

|

THE RA-180

The RA-180 is a RIGID® airship with a fabric outer skin stretched over an aluminium frame which contains a series of separate gas compartments. This distinguishes it from two other types of airship: the ‘blimp’ and the semi-rigid type. The blimp is effectively just a large balloon filled with gas. This is also true of the semi-rigid type, except that it has a keel. Thanks to the combination of its aluminium construction and separate gas compartments, the Rigid airship is the safest type of airship.

The RA-180 has a robust skeleton construction consisting of lightweight aluminium ring girders, longitudinal girders and bracing wires. Between each set of ring girders lies an immense, fireproof laminated mylar cell into which helium (He) is fed. The 180-metre long by 30 metre wide airship will contain 20 separate compartments capable of holding up to 78,000 m3 of helium. The gigantic skeleton is covered by a strong synthetic fabric skin. This creates a gross volume of 83,100 m3, which also provides room for the engines, cargo and passenger accommodation – all of which lie inside the skin. The only things which protrude outside this skin and thus interrupt the vessel’s aerodynamically perfect cigar shape are the propellers, fins and the pilot’s control cabin.

Propulsion system

The RA-180 has four tilting propellers for take off and landing. These, together with the two fixed propulsion propellers, are each powered by 600 h.p. reciprocating engines. The 3,600 h.p. they generate together feed the propellers to create a top speed of 148 km/hour or a radius of action of no less than 20,000 kilometres. To offset the loss of the weight of fuel and to prevent the vessel from gaining altitude, the engines can be fitted with condensers which convert the exhaust into water. This keeps the weight and altitude stable. An airship does not have to overcome gravity to climb higher and no energy is required to maintain altitude. The airship’s relatively low fuel consumption and the fact that it does not, in principle, consume helium make it a cost-effective and energy-efficient method of air transport.

Ready for lift-off

The RA-180 can carry up to 30 tonnes of cargo or 240 passengers. To this end, a large area has been reserved inside the hull which has been built into the construction like a box. Transport by airship is ideal for bulky, lightweight freight. Since one cubic metre of helium can lift around a kilogram, the total lifting capacity of the RA-180 is over 78 tonnes. Minus the weight of the structure and the engines, this leaves approximately 30 tonnes for useful lift.

|

|

In addition to a series of smaller buildings, a hangar will be built which will be big enough for the assembly of a 180 meter long airship. Two large landing circles will also be provided, with a mast at their centre where the airships can moor and around which they can swing head to wind direction. In addition to the wide support the project has been given by Dutch industry and government, The Netherlands was selected as a location due to its flat landscape, which is ideal for airships, its environmental focus, its excellent infrastructure and the presence of good suppliers.

Rigid Airship Design N.V. received many invitations to locate in several municipalities. However, Lelystad was chosen because of the local council’s enthusiasm for the proposed plans, the ideal siting of the selected premises close to the IJsselmeer and the sheer space available for carrying out test flights. It will take out a phased lease (with an option to buy) on a site of up to 220 ha on the ‘Flevo coast’ to the north of the town (a location formerly known as the Visvijver area). Not only does the site provide enough room for the company’s planned activities and anticipated expansion, its location on the edge of the IJsselmeer also makes it an ideal home port and point of departure for the test flights.

Rigid welcomed in Lelystad

The local authorities in Lelystad enthusiastically welcomed Rigid Airship Design N.V. to the town. Not only for the employment it will create but also because airship design is a new industry which will add to the modern image of Lelystad and because the project applies innovative, environmentally friendly technologies. This ties in very well with the image the Flevopolder wants to create of an area with clean air, water and soil.

Support and co-operation

In addition to contributions from Dutch companies, Rigid Airship Design N.V. can also count on scientific support from the Aerospace Faculty at Delft University of Technology and co-operation from the Dutch Civil Aviation Authority. The initiative also enjoys the broad interest of the European Union, the Dutch government and the Ministries of Transport, Public Works and Water Management, of Economic Affairs and of Housing, Spatial Planning and the Environment. Of course the company is also working closely with the municipality of Lelystad, where Rigid Airship Design N.V. now has its design offices.

Employment

Once construction work begins on the airship, the number of jobs at Rigid Airship Design N.V. in Lelystad will gradually rise from 200 to 250. If the tests are successful and the airships can be mass produced, the project could generate enough work for a total of 1,300 people, including suppliers. The first hangar to be built will be able to accommodate the construction of four large airships each year. The site also provides room for further – even bigger – hangars, giving Rigid Airship Design N.V. more than enough room for further growth.

THE HANGAR:

one of the biggest construction projects in The Netherlands

The hangar to be built on the site at Lelystad will be large enough for the assembly of one airship at a time. In order to be able to construct the first airship prototype, a hangar will be needed measuring approximately 237 metres in length, 48 metres in height and 73 metres in width. When it is finished, it will be more than twice the height of the Rembrandt Tower in Amsterdam.

Construction

Construction work on the hangar will start during the second half of 1999; the provisionally planned starting date is September of this year. The construction permit was submitted to the Lelystad municipal council at the beginning of April. The architect is W.S.P. Holland, based in the Hague. It is not yet known which construction company will be building the complex.

Its sheer size, volume and architectual design will make the hangar a real eye-catcher and a building that is unique.

The hangar will take around 10 months to complete. It can then be put into use straightaway for the assembly of airships. Components for the airships will be made in various locations throughout the Netherlands, but all the assembly work will be done in the hangar at Lelystad.

|

|

FREQUENTLY ASKED QUESTIONS

|

|

1.

What is an airship?

An airship is an airborne vehicle obtaining most of its lift from lighter-than-air (LTA)gas (generally helium) contained in the vessel’s envelope (or in separate gas cells). Additional lift is provided by the aerodynamic contour of the vessel; this may be supplemented during take-off and landing by the application of vectored thrust provided by the engines. Since most of the airship’s lift is derived from the helium, the engines are needed mainly to move the vehicle through the air and, to a lesser extent, to provide power for the avionics. This results in considerable fuel economy compared with heavier-than-air (HTA) types of craft and produces much reduced emissions.

There are 3 main types of airships: rigid, semi-rigid and non-rigid.

|

click on picture to enlarge

|

|

-

The rigid airship maintains its shape and rigidity by an internal framework. The lifting gas is contained in a series of separate gas cells within the main structure; the structure is enclosed by the outer cover or envelope. Accommodation is carried within the structure.

-

The semi-rigid airship maintains its shape and rigidity by the pressure of the lifting gas directly within the gas-tight envelope but supplemented by either an internal or external keel.

-

The non-rigid or pressure airship maintains its shape by the pressure of the lifting gas directly within the gas-tight envelope, supplemented by an adjustable volume of air within ballonets. Today most airships are of this type and use helium as the lifting gas. A non-rigid or pressure airship is often referred to as a blimp.

|

|

back to questions

2.

Why is the Rigid Airship superior?

The Classic Rigid Airship is the only type of airship to have demonstrated success in commercial airship operations at a level beyond that of advertising and short endurance passenger joy rides. Despite a large number of proposals having been made to develop other airship types to operations in full commercial passenger and freight transport, no proposal to date has succeeded in commercially undertaking such use.

The Rigid Airship is the only airship type with the proven capability to maintain controlability and structural integrity at flight speed in the event of loss of a gas containment element.

The Rigid Airship provides an insulating air layer between the outer environment and the lifting gas, thereby eliminating the immediate and significant variation in gas lift which occurs in other airship types as a result of variations in sunlight.

The Rigid Airship provides a structure capable of housing the power plants at points on the optimum line of thrust within or external to the hull, thereby reducing drag while maintaining maximum aerodynamic efficiency.

The Rigid Airship’s structure prevents aerodynamic flexure, thereby increasing speed (or reducing fuel consumption) by around 10% when compared with other airship types.

back to questions

3.

What is so special about an airship?

An airship can be more spacious than any other aircraft. It also has the unique advantage of being able to stay airborne for long periods. Whereas fixed and rotary wing aircraft measure flight time in hours, an airship can stay aloft for days or weeks.

back to questions

4.

Are airships safe?

Yes.

First: helium is not only non-flammable but can actually extinguish fire. Second: a modern airship’s advanced, robust structural and fabric materials as well as its sophisticated mode of propulsion and flight control, make it extremely safe to operate even in bad weather. Goodyear have proven in their operations since the late 1930’s until the present that modern airships have by far the best safety record of any type of flying vehicle.

back to questions

5.

How can a lighter-than-air vessel operate in severe weather?

A rigid airship is not a free balloon, its aluminium framework and multiple engines produce a vehicle which, even before World War II, was capable of operating a scheduled service in the severe weather conditions experienced over the North Atlantic Ocean. During US government tests in the 1950’s the airships’ weather ability exceeded that of fixed wing aircraft even in long duration radar operations conducted in what were often FULL gale conditions.

back to questions

6.

How fast do airships travel?

An airship is, in general, a low speed vehicle or platform. It is unlikely to exceed 148 km airspeed. But an airship is considerably faster than most surface alternatives. What it lacks in speed it more than makes up in its operating flexibility.

back to questions

7.

What happens if the envelope is punctured?

Unlike a toy balloon, the lifting gas in a pressurized airship, a so called blimp, is maintained at a very low pressure (just sufficient to maintain its shape). In a rigid airship there is no pressure at all. Should a small hole occur, the escape of gas would be slow. Even with a large number of small holes the buoyancy would not be substantially effected immediately, and can be repaired during periodic maintenance inspections.

A large hole in a gas cell on a rigid airship would mean that the airship’s mission would have to be aborted but the ship could still return to base for the necessary repair. Even in such circumstances the airship would be capable of remaining aloft and landing safely.

|

|

PICTURE GALLERY

CLICK ON THEM TO ENLARGE

|

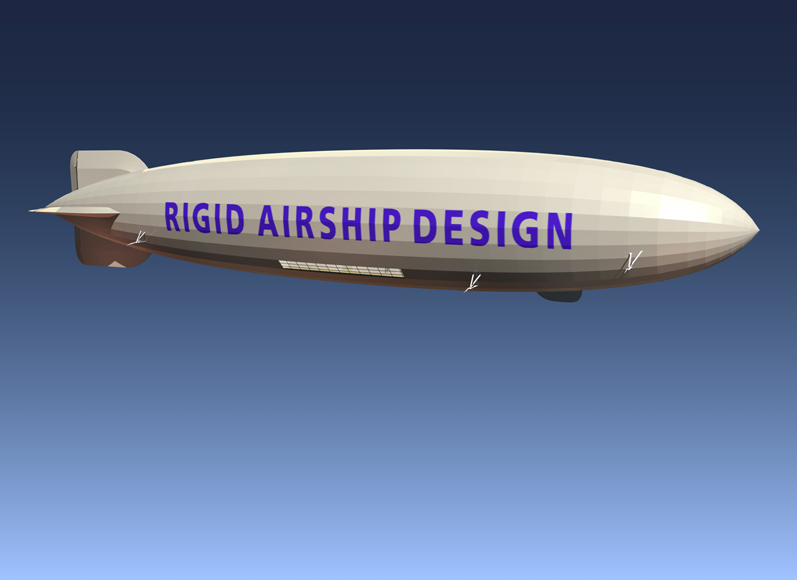

Holland Navigator

|

Glimpse of the Future

|

Two men behind a Big idea

|

Inside view

|

1st scale model

|

|

|---|

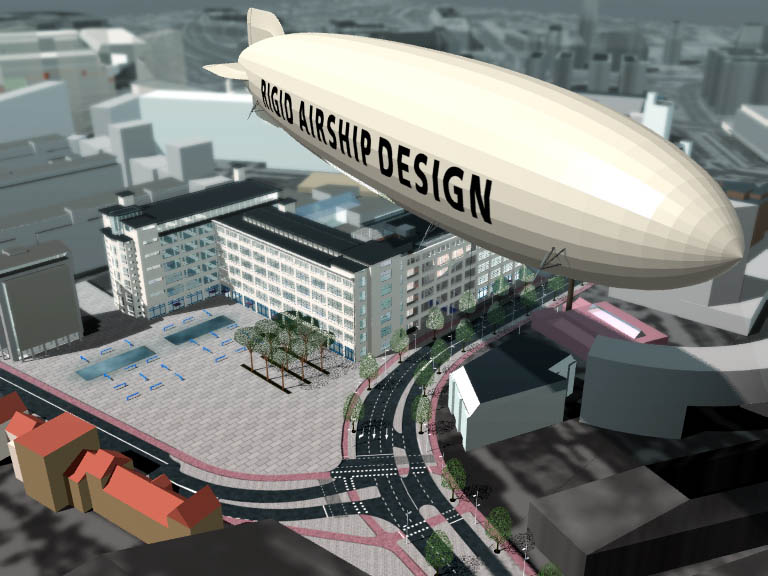

Site impression

|

Inside View

|

Artist Impression

|

Site impression

|

|

|---|

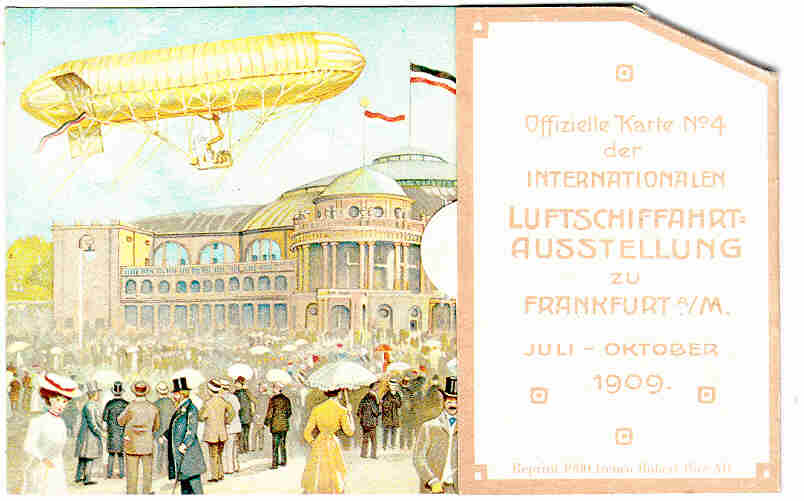

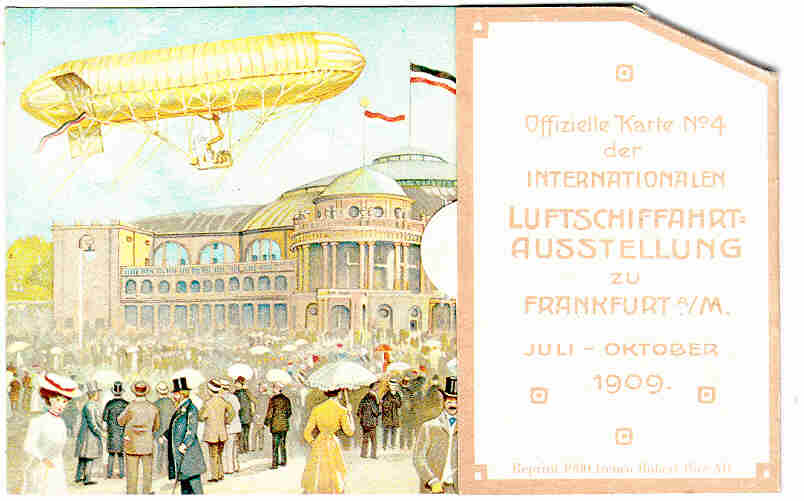

Ticket 1909

|

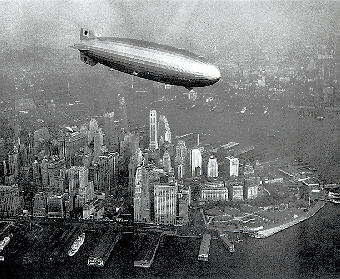

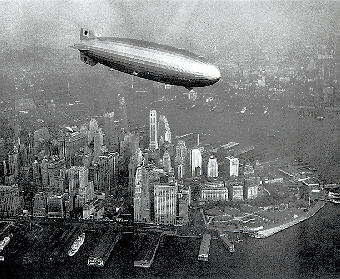

Hindenburg over New York

|

Luxury interior

|

Graf Zeppelin over the Alps

|

Graf Zeppelin Poster

|

|

|---|

Airship over Lambs

|

At the mast

|

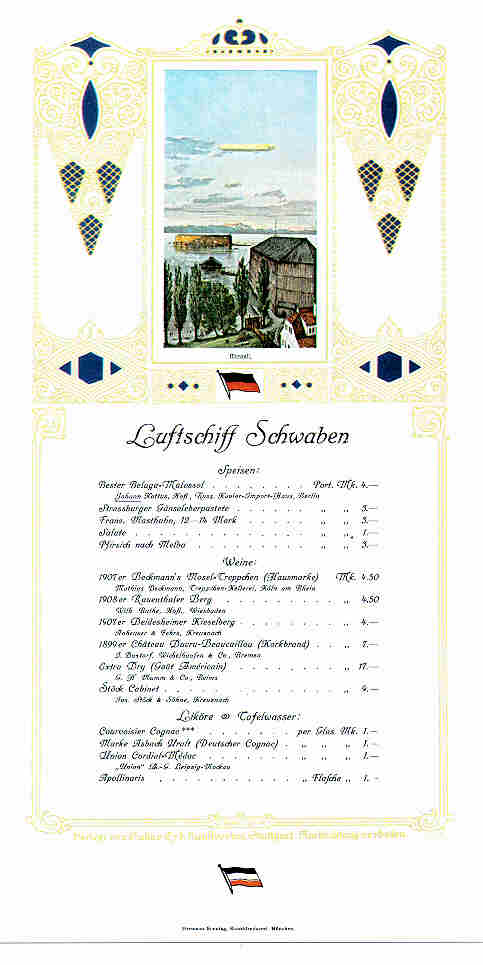

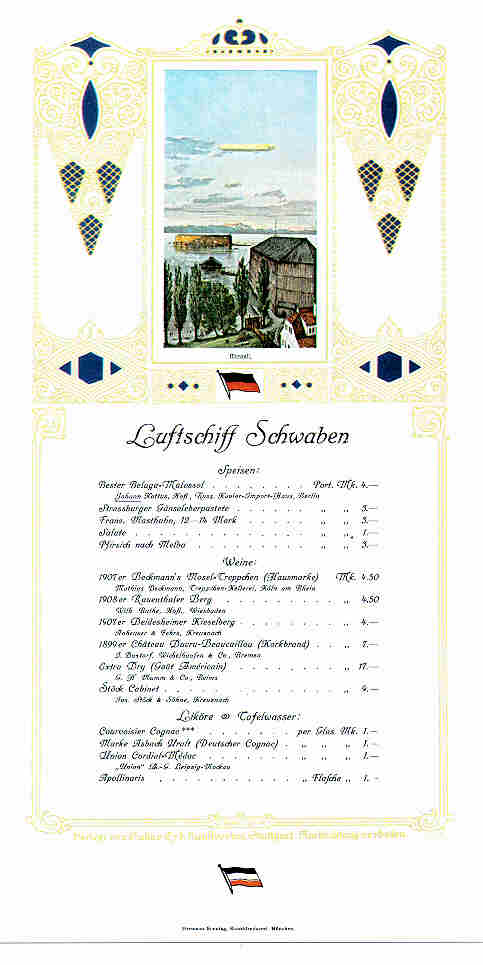

Menu Luftschif Schwaben

|

Young Mr. Alexander

with his father

|

Ian Alexander

at Zeppelin

|

|

|---|

|

|

CHECK THIS PAGE FREQUENTLY!

'IF THERE IS NEWS TO TELL, IT WILL BE HERE'

|

On 24 June 1999, our web-site received a

Merit Award

A recognition for quality sites!

|

|

's-Graveland, 4 June 1999

"Copy of a recent address from Ian Alexander at a meeting of the German DGLR (Deutsche Gesellschaft für Luft- und Raumfahrt) in Bremen, Germany"

The Realities of Large Airship Design

The immediate problem which confronts an aspiring designer of large airships is a financial one. No investor will support a company which proposes to design an artifact for which there exists no production capability. Therefore to be acceptable to investors the entrepreneur must propose not simply to design an airship but also produce a business plan covering procurement of a large area of land, construction hangar and manufacturing infrastructure, and the necessary ground handling equipment. His proposal must also contain financial provision for the tooling and necessary production workforce to build the airship as well as to design it. This requires an enormous investment with considerable risk, since the entrepreneur is unlikely to obtain firm orders for his proposed product until the project is well underway, and the expenses of airfield, hangar, ground equipment and tooling have already been committed.

If the entrepreneur achieves any degree of interest among financiers he will speedily learn that in an enterprise with the magnitude of a large airship project governmental involvement and commitment is essential. Subsidies will almost certainly be sought before finaniciers are likely to invest, and to have any serious hope of achieving these subsidies it is necessary that the government clearly understands the project. This too is a time consuming activity, since politicians are active individuals who are much in demand and wary of the unusual, which can all too easily be portrayed as the eccentric.

However, if we assume that the entrepreneur, against all odds, succeeds in achieving funding and political support, he is then confronted with the fact that his proposed airship must fulfil the requirements of a modern aircraft certification body. All pre-1940 large commercial airships were inflated with hydrogen. This is no longer permitted, and the lift penalty of operating and airship helium rather than hydrogen is not merely a straightforward matter of the relative lift of the two gases. The realistic requirement is an increase in design volume of around 20% to achieve the same performance as would be attainable on hydrogen.

The onus of proof regarding the airship’s safety will lie with the company, and since the company is unlikely to be able to prove the reliability of structures and systems from adequate historical experience, the test schedule is likely to be exhaustive.

A modern aeroplane requires between four and five years to achieve full certification, and a large airship is unlikely to reduce this requirement. Indeed, because of the total lack of experience with large airships in all modern certification authorities, the required period to certification may well be even longer that that required for an aeroplane.

But let us again assume that our entrepreneur has survive all of the above processes and has produced a certificated large airship. Such an airship is unlikely to be acceptable to many existing large airports, not only because of the airship’s necessarily large mooring circle, but also because the comparatively slow approach may interfere with the crowded landing and take off schedules of aeroplanes.

Therefore dedicated airship terminals will be required. These terminals, if the airship is to make any significant impact on transport, will require to be able to accept several large airships at any one time, and will consequently require large areas of land to permit multiple mooring circles.

We often hear that airships, because of their low noise and low pollution, will be able to land in areas closer to cities than would be permitted to aeroplanes, but large areas of open flat land close to cities are both expensive and rare. The city centre high masts, much vaunted by enthusiasts, are unlikely to be permitted in the foreseeable future, since certification authorities will require many years, if not decades, of safe operation at conventional masts before even considering such proposals.

The above is a truly daunting list of hurdles to any prospective large airship entrepreneur, and this list is by no means exhaustive. But it may go some way to explaining why no large airship has been built for over sixty years. However, at least three companies are now seriously engaged in the design of such airships. Why has this sudden eruption of large airship companies happened now, and how have the above difficulties been overcome. I can speak only for my own company, Rigid Airship Design N.V. of Holland, therefore I will recount our experiences over the last three years.

I had reflected for many years that the Commercial Rigid Airship had had rather a bad press. Their abrupt termination on the “Hindenburg” disaster in 1937, twenty seven years after the founding of DELAG may seem a little unreasonable to a generation which has become accustomed to an almost weekly diet of total loss aeroplane disasters. No previous commercial Zeppelin had ever injured, far less killed, a passenger, and even the “Hindenburg” spared two thirds of those on board. Yet the LZ-129’s spectacular end effectively terminated commercial use of Rigid Airships worldwide.

I had been involved in airships since the early 1960’s. The first airship which I assembled was the ex US Navy L-19, which we flew to Holland from Germany for an advertising contract in 1963. I had retained fond memories of the Dutch overflights, and by a co-incidence a Dutch Company, FESTO B.V., had become a major investor in Imperial Airships Ltd, a Manx Company which I established in the late 1980’s to provide the security airship for the Barcelona Olympic Games.

After the Games the Managing Director of FESTO B.V. asked me if I had ever considered producing a larger airship, and I replied that I had often considered this, but that I believed that a really large airship could best be produced from the classical Rigid design. “Why don’t you have a go?” he asked.

That evening I gave the matter serious thought. It would be difficult to identify a country more appropriate for such an endeavour than Holland. The country is flat, has large stretches of inland water for test flying, and contains one of the world’s finest aeronautical faculties at the Technical University of Delft. It contains a major certification authority, with reciprocity with both the FAA and the CAA, and by co-incidence there were a large number of experienced aircraft designers and builders unemployed as a result of the collapse of Fokker. Holland’s industrial capability rendered it possible to obtain almost all components required for a modern Rigid Airship within the country.

Holland had additional attractions. The country’s existing transport infrastructure was under severe strain, and it was actively seeking alternative transport media. In addition public attitudes favoured environmentally friendly and sustainable solutions. Finally, Holland exports many tons of flowers every day to both England and Sweden, cargo that is both bulky and journey time dependent. Airship transport would surely be preferable to the lorry, ferry, lorry arrangements then in place.

Having decided that, if I undertook a Rigid Airship Project at all, it would be in Holland, I then began to evolve a strategy. I realised that, since Holland has almost no airship experience whatsoever, it would be necessary to educate the financiers, the public and the politicians. I appreciated that this would take considerable time. Even in the Germany of 1926, where popular knowledge and awareness of airships was almost universal, Eckener had to spend two years organising fund raising lectures throughout the country to enable the LZ-127 to be built. Therefore, if I were to build a Rigid Airship in Holland, I could expect to spend at least the first two years on an educational mission.

I began with the financiers. By the greatest good fortune I was introduced to a gentleman who was prepared to take a long term view, and who believed wholly in the Rigid Airship Project. From an office he provided I began a series of lectures throughout the country which lasted slightly longer than the two years which Eckener required. I visited Holland’s certification authority many times during this period, and gradually led its staff to move from bemused incredulity to serious consideration and ultimately acceptance of the validity of the Rigid Airship Concept.

Helped by Dutch colleagues I gently lobbied politicians, and was enormously assisted by the Junge Coalitie, an inter-party group of young potlitical aspirants, who gave public debates on the subject of airships in all the major cities of Holland. This led ultimately to the Dutch Prime Minister, Wim Kok, announcing in parliament that “Holland needs Rigid Airships for commerce.”

With such support an industrial consortium was formed, consisting of two of the largest companies in Holland, RDM Technologies and Stork, together with a group of financiers and investment companies.

We expanded the core team which had come together during the “lecture years” into a design team of around thirty, largely comprised of ex-Fokker employees. The town of Lelystad, in the province of Flevoland, offered us an area of land on the edge of the Ijselmeer, more than adequate to house a large airship port. Emminent Dutch architects offered their services to design our hangars, and the Technical University Architectural Faculty instituted a yearly prize to its students on airship hangar design. Regional airports in Holland began to express interest in utilizing airships for internal flights, where the small size of Holland made the slower airspeed of the environmentally friendly airship less significant than it would be on the longer routes of larger countries.

We restricted ourselves to an airship of a size adequate to profitable operation while re-proving the Rigid concept, thereby keeping the required investment as low as possible and accommodating as much as possible the inescapable lack of experience of modern crews regarding large airships.

The RLD, the Dutch Certification Authority, has joined with the LBA in the production of “Transport Airship Requirements”, the design requirements for large airship, including ours. Rigid Airship Design has submitted its comments on these requirements, in common with other airship companies. We have applied for our Design Organization Approval and Type Certificate, and have already received orders for two Rigid Airships of 180 meters from Rigid Airship Inc, USA. This order carries with it our approval of the American Company’s request for the right to build subsequent airships to our design under a royalty payment. When the press reported this a few months ago there was quite a furore on the internet airship ‘chat lines’. The fact that an American Company had agreed to pay a royalty to Rigid Airship Design for the right to build Classical Rigid Airships to our designs caused one net user to remark that anyone could design and build a Classic Rigid Airship, and that the concept of a royalty based licence to build such a vehicle was ridiculous and on the face of it this statement appears to be correct. Classical Rigid Airships were used from 1910 until 1937 in passenger transport with an overall safety record more than appropriate to the technology and expectations of the time.

But consider this:- A ten year old schoolboy writes to me regularly, and is kind enough to send me drawings of the large Rigid Airships which he designs with equal regularity. The most notable feature of his designs is the large sweetshop which appears at the centre of each passenger deck. Yet Nicholas’ designs would have just about as much hope of achieving modern certification as would those of the LZ-130. To-day’s certification requirements are severe, and those who believe that we can merely start where the pre-war designers left off are sadly deluded.

Today’s large airship designer must create a whole range of new structures and systems to meet today’s requirements. We must develop an airship to standards at least as exacting as those required of the largest aeroplanes. We must demonstrate at least as high a safety factor. These things are not achieved easily. But we can achieve them, and, as our American customer has realized, such achievements merit a royalty from those who wish to build to our design. Further our comparatively long-standing relationship with the RLD gives us the realistic hope of a certification process, being as speedy as is possible.

I believe that we were uniquely fortunate in our timing and location. With to-day’s crowded upper atmosphere an alternative aircraft which exploits the comparatively empty lower atmosphere has become desirable, as has the Rigid Airship’s sustainable and environmentally friendly technology. With the end of the cold war a large number of ex-military large airfields, currently unused by heavier than air, have become available to large airship operators. Road congestion, particularly in Holland, has become almost intolerable, and short-haul airship travel is an attractive alternative. We were also fortunate in that a substantial and competent design staff was available to us in Holland at the time we instigated the project, together with a government which was prepared to take the time needed to understand an unusual and novel development which less open-minded politicians might well have dismissed. In fact that we have been in communication with the RLD since 1995 has ensured that it is the certification authority next familiar with the Rigid Airship concept. This in itself goes some way to optimizing the certification process. There is widespread awareness in Holland that the modern Rigid Airship’s time has at last come. Already a major Dutch Marketing Research Company, NIPO, at the request of the Jongeren Coalitie, has established that more Dutch residents would prefer to fly to London by airships than by aeroplanes. I do not believe that it will be long before this awareness spreads beyond Holland’s borders.

***

|

|

DUTCH RELEASE

Perbericht

Lelystad, 8 april 1999

Bouw luchtschepen komt in zicht

In Nederland wordt binnenkort begonnen met de bouw van luchtschepen. Dat maakten de leden van het consortium van Rigid Airship Design N.V. vandaag bekend. In dit consortium nemen naast de initiatiefnemer, vertegenwoordigd in Airshot International N.V., ook RDM Aerospace N.V., Stork N.V., Greenfield Capital Partners B.V. en M. Caransa B.V. deel. Om de bouw mogelijk te maken verrijst nabij Lelystad een enorme hangar, waarvan de aanvang van de bouw vooralsnog gepland staat in september van dit jaar. De bouwvergunning daarvoor is inmiddels aangevraagd.

Met de bouw van de luchtschepen wil het consortium een belangrijke aanbieder zijn op de markt van vervoer en transport. Uit haalbaarheidsonderzoeken blijkt dat er in de komende 20 jaar een markt is voor zeker 1000 luchtschepen, die voor het vervoer van vracht en passagiers zullen worden ingezet. Ook in het verleden is bewezen dat volgens vastgelegde tijdschema's en vluchtroutes werd gevlogen met luchtschepen, zowel binnen Europa, als intercontinentaal. Vliegen met luchtschepen staat bekend als opmerkelijk rustig en zeer comfortabel.

De in Nederland te bouwen luchtschepen zijn van het zogenaamde rigide type wat betekent dat ze een stevige kooiconstructie hebben en bestaan uit diverse afzonderlijke gascompartimenten. Vliegen met deze 'rigid airships' is een veilig en schoon vervoersalternatief door de lucht door het gebruik van het branddempende heliumgas en zeer geluidarme en energiezuinige motoren.

Het is de verwachting dat medio 2001 het eerste luchtschip klaar zal zijn. Dit prototype zal 180 meter lang zijn met een diameter van 30 meter. Het beladingsvermogen bedraagt zo'n 30 ton, de maximale snelheid en actieradius zijn respectievelijk 148 km per uur en 20.000 km. Het luchtschip kan tot 20 dagen onafgebroken in de lucht zijn. Een luchtschip van deze afmeting zal ongeveer fl. 60 miljoen gaan kosten. Inmiddels hebben diverse partijen interesse getoond voor de luchtschepen.

Noot voor de redactie:

Een persmap en een videoband zijn via

E-MAIL opvraagbaar

|

|

U.S.A. RELEASE

Company Press Release

Monday April 12, 10:05 am Eastern Time

SOURCE: Rigid Airship USA, Inc.

Building of Airships Project Ready for Take-off in Holland

STONE HARBOR, N.J., April 12 /PRNewswire/ -- Plans to start building classical airships in the Netherlands were announced April 9 by the members of the Rigid Airship Design N.V. consortium. Brought together by Airshot International N.V., the consortium also includes RDM Aerospace N.V., Stork N.V., Greenfield Capital Partners B.V., and M. Caransa B.V. Work on the construction of a vast hangar near Lelystad, Holland, in which the airships will be built, is scheduled to commence in September.

The consortium intends to be an important player in the travel and transport market. Several feasibility studies project that there will be a market over the next twenty years for at least 1,000 airships to carry both passengers and freight. Past experience has demonstrated that airships are capable of operating scheduled services on fixed routes, both European and intercontinental. Flying by airship is remarkably quiet and extremely comfortable. Rigid Airship USA (OTC BB:RAIR) will be training its engineers at the Lelystad plant, where two 180-meter airships will be constructed for the new American airship company.

The airships to be built in the Netherlands will be of the rigid type, incorporating a stiff cage within which the "envelope" is divided into a number of separate gas compartments. Rigid airships, using fire-suppressing helium gas and fitted with very quiet, energy-efficient engines, are a safe and clean alternative to conventional aircraft.

The first airship is hoped to take to the skies in 2001. This prototype will be 180 meters long and 30 meters in diameter. This airship will have a useful lift of approximately 30 tons and a maximum speed of 148 km/h. Its maximum operating radius is 20,000 km. For surveillance purposes the airship will be able to stay aloft for up to twenty days. An airship of this size will cost around US $30 million. Compared to conventional fixed-wing aircraft with similar capacity, airships present an uncommonly low cost to purchase and operate, and global response to the return of classical airships has been highly positive.

SOURCE: Rigid Airship USA, Inc.

More Quotes and News: Rigid Airship USA Inc (OTC BB:RAIR)

|

|

Published articles (newspapers / magazines) regarding Rigid Airships over the last years, archived by Rigid Airship Design.

Summary

Name / publication / Country / Date / Heading

-

Volkskrant (NL):

31 December 1998,

"Zeppelin"

-

NRC Handelsblad (NL):

31 December 1998,

"Zeppelinfabrikant komt naar Lelystad"

-

De Telegraaf (NL):

31 December 1998,

"Fabrikant van luchtschepen naar Lelystad"

-

De Gelderlander (NL):

5 December 1998,

"Zeppelins kunnen interessante aanvulling zijn op luchtvervoer"

-

Haagsche Courant (NL):

5 December 1998,

"Verkeer voor inzetten van Zeppelins"

-

Aktueel (NL):

19 November 1998,

"Herrijzenis van de Zeppelin. Goedkoper, veiliger, stiller en schoner dan gewoon vliegen"

-

FNV Magazine (NL):

October 1998,

"Productie Zeppelin nog luchtfietserij"

-

Management Team (NL):

23 October 1998,

"Durf in Technology Techno drammers"

-

Algemeen Dagblad (NL):

26 September 1998,

"Markt voor luchtschepen niet overschatten"

-

Nieuwsblad van het Noorden (NL):

17 September 1998,

"Luchtverkeer"

-

Het Financieel Dagblad (NL):

10 September 1998,

"Nederlands consortium wil starten met bouw luchtschepen"

-

Algemeen Dagblad (NL):

9 September 1998,

"Nog even dit/Jongensdroom"

-

Gasbag (NZ):

September 1998,

"Bedford convention review"

-

Algemeen Dagblad (NL):

5 September 1998,

"Zeppelins zijn het luchtfietsen voorbij"

-

Gooi & Eemlander (NL):

1 September 1998,

"Zeppelin-bedrijf wil snel fabriek bouwen"

-

De Gelderlander (NL):

1 September 1998,

"Luchtschip lijkt geen luchtkasteel meer"

-

BN/De Stem (NL):

1 September 1998,

"Luchtschip lijkt geen luchtkasteel meer"

-

Brabants Dagblad (NL):

1 September 1998,

"Luchtschip lijkt geen luchtkasteel meer"

-

Amigo (Curacao):

31 August 1998,

"PR-plan voor Zeppelin"

-

Flevoland Dagblad (NL):

31 August 1998,

"Zeppelin fabriek heeft haast"

-

Volkskrant (NL):

31 August 1998,

"Stork en RDM willen Zeppelin bouwen"

-

De Telegraaf (NL):

31 August 1998,

"Stork en RDM doen samen onderzoek naar bouw Zeppelin"

-

Algemeen Dagblad (NL):

29 August 1998,

"Zeppelin bij RDM en Stork/Luchtschepen naar de Spaanse zon"

-

Sunday Times (GB):

17 August 1998,

"Army calls up airship to active duty again"

-

Amigo (Curacao):

August 1998,

"De wereld volgens Joes Wanders"

-

Financial Times (GB):

25 June 1998,

"Airships: Industry prepares for take-off"

-

Haagsche Courant (NL):

20 June 1998,

"Vreedzaam snorrend boven de Hollandse velden"

-

Management Team (NL):

5 June 1998,

"Airship Enterprise"

-

Energie Verslag Nederland (NL):

4 June 1998,

"De Zeppelin als milieuvriendelijke doorbraaktechnologie"

-

Het Financieel Dagblad (NL):

8 May 1998,

"Bloemenveiling ziet redding in Zeppelin"

-

Luchtlogistiek (NL):

2 May 1998,

"Markt voor luchtschip moet zich nog bewijzen"

-

De Gelderlander (NL):

29 April 1998,

"Tulpen uit Amsterdam mogelijk per Zeppelin naar het buitenland/Zeppelin lijkt bij uitstek geschikt voor bloementransport"

-

Logistiek Magazine (NL):

23 April 1998,

"Transport bloemen mogelijk met Zeppelins/Bloemenvervoerders zoeken naar ruimte"

-

International Herald Tribune (GB):

16 April 1998,

"Al Haig Bets on Zeppelins As Alternative to Satellites"

-

Mercedes Magazine (NL):

April 1998,

"De moderne dinosauriër"

-

Trouw (NL):

7 March 1998,

"Luchtschip zou uitkomst voor minister Pronk zijn"

-

Kijk ( jeugdblad )(NL):

March 1998,

"Het luchtkasteel is terug"

-

The Sunday Times (GB):

1 March 1998,

"Giant airship blazes new trails in sky"

-

Het Parool (NL):

28 February 1998

"Nieuwe kans voor de Zeppelin"

-

Het Zuiden [Rotterdam e.o.] (NL):

26 February 1998,

"Hedendaagse luchtschepen zijn geen vliegende Titanic’s meer"

-

Utrechts Nieuwsblad (NL):

17 January 1998,

"Zeppelin van 242 meter goed voor vrachtvervoer van 160 ton

Grote zwevende sigaar keert terug"

-

Het Financieele Dagblad (NL):

23 December 1997,

"‘Glare’, een bijna-rijpe vrucht van wilde promovendi"

-

Het Financieele Dagblad (NL):

20 december 1997,

"Postmoderne ‘Hindenburg’ begint bij einde"

-

De Dordtenaar (NL):

10 December 1997,

"Transport per luchtschip"

-

Volkskrant (NL):

8 December 1997,

"In twee dagen naar New York"

-

EOS-magazine (NL):

December 1997,

"Het tweede leven van de zeppelin"

-

The Observer (GB):

30 November 1997,

"Airship reborn as green jam-buster"

-

De Telegraaf (NL):

20 November 1997,

"Kok wil ov-zeppelin"

-

Limburgs Dagblad (NL):

15 November 1997,

"Luchtkasteel of proefballon?"

-

Holland Herald/Inflight magazine KLM (NL):

October 1997,

"Ballooning mobiles"

-

Algemeen Dagblad (NL):

7 October 1997,

"Zeppelin geeft Schiphol lucht"

-

Het Financieele Dagblad (NL):

22 September 1997,

"Zeppelin na bijna zestig jaar weer terug"

-

USA Today (USA):

11 September 1997,

"From the ashes arise new, safer zeppelins/Modern airships cultivate niche in industry, travel"

-

The Sunday Times (GB):

27 July 1997,

"Flight of fancy"

-

The Independent (GB):

25 July 1997,

"German left takes refuge in Zeppelin"

-

De Hitkrant ( jeugdblad )(NL):

19 July 1997

"60 jaar na De Hindenburg: Zeppelin niet langer de sigaar"

-

Herald-Tribune (GB):

20 June 1997,

"Airbus Gets an Order From Northwest"

-

YES [ jeugdblad] (NL):

till 14 June 1997,

"Wie gaat er mee in de Zeppelin?"

-

Drentse Courant/Groninger (NL):

3 June 1997,

"Luchtschipbouwer wilde graag naar Noorden komen"

-

Haarlemsch Dagblad (NL):

24 May 1997,

"Proefballon of klapsigaar"

-

De Telegraaf (NL):

17 May 1997,

"De geheime liefde van Martin Schröder"

-

Cursor [TU Eindhoven] (NL):

15 May 1997,

"Zeppelins: duurzame vervoermiddelen of fopsigaren?"

-

Flight International:

13 May 1997,

"Zeppelin ready for historic return"

-

NRC Handelsblad (NL):

10 May 1997,

"High Tech Zeppelin attractie van de toekomst"

-

The Sunday Times (GB):

4 May 1997,

"Russia faces space station exclusion"

-

Financial Times (GB):

3/4 May 1997,

"Rebirth for the giants of the sky"

-

Elsevier (NL):

10 May 1997,

"Een vliegtuig is veel te haastig"

-

Intermediair (NL):

3 April 1997,

"Nieuwe Luchtvaartindustrie in Nederland"

-

Milieudefensie (NL):

20 December 1996,

"Rabobank steekt geld in de Zeppelin"

-

Trouw (NL),

20 December 1996,

"Groenfonds steekt geld in bouwproject voor Zeppelins"

-

Algemeen Dagblad (NL):

7 December 1996,

"De vliegende sigaar komt terug"

-

Algemeen Dagblad (NL):

11 November 1996,

"Zeppelin op wereldreis"

-

Gelderlander (NL):

1 November 1996,

"Luchtschip of luchtkasteel?"

-

Technisch weekblad (NL):

November 1996,

"Zeppelin terug?"

-

Limburger (NL):

26 October 1996,

"De Zeppelin: luchtschip of luchtkasteel"

-

Amersfoorts Dagblad (NL):

10 October 1996,

"Nieuwe kans voor het luchtschip"

-

Panorama (NL):

9 October 1996,

"Fokker is failliet, maar we krijgen een nieuwe Nederlandse luchtvaart-Industrie. Revolutionair: In 2000 gaan we met

de Zeppelin!"

-

Ballon- en luchtscheepvaart (NL):

3 October 1996,

"Nederlandse bedrijven willen luchtschepen bouwen"

-

Nieuwsblad Transport (NL):

1 October 1996,

"Zeppelin: alternatief sea/air?

Belangstelling Fokker voor Zeppelin gepolst"

-

Utrechts Nieuwsblad (NL):

28 September 1996,

"Met de Zeppelin naar de zon"

-

De Volkskrant (NL):

27 September 1996,

"Zeppelin kan concurrentie met touringcar aan"

| |